MMOOKA

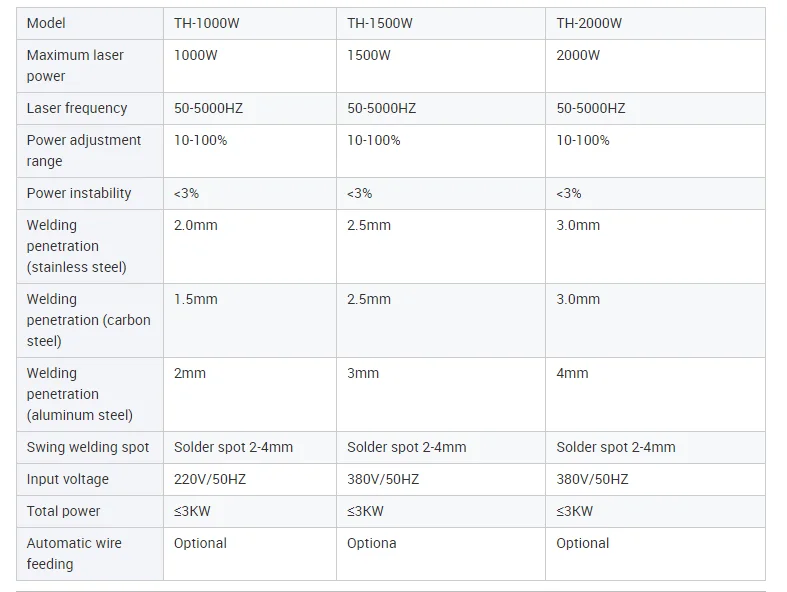

Handheld Weld Equipment Cheap 1000W 1500W 2000W Fiber Handy Laser Welder For Metal Fiber Laser Welding Machine

Handheld Weld Equipment Cheap 1000W 1500W 2000W Fiber Handy Laser Welder For Metal Fiber Laser Welding Machine

Couldn't load pickup availability

About Freight

If you have any questions about the freight, please consult us

Product Description

Laser welding is to use high-energy laser pulses to locally heat the material in a small area. The energy of the laser radiation diffuses into the interior of the material through heat conduction, and the material is melted to form a specific molten pool. It is a new type of welding method, mainly for the welding of thin-walled materials and precision parts, and can realize spot welding, butt welding, stitch welding, sealing welding, etc. Small deformation, fast welding speed, smooth and beautiful welding seam, no need or simple treatment after welding, high welding seam quality, no pores, precise control, small focusing spot, high positioning accuracy, and easy automation.

Product Parameters

Product Features

● Beam quality number, with very good monochromaticity, directionality and stability;

● low cost;

● High conversion efficiency;

● There are many output wavelengths, tuning precautions;

● Good temperature stability;

● Simple structure and small footprint;

● Since there is no optical mirror in the resonator of the fiber laser, the cavity mirror of the resonator can be directly fabricated on the section of the fiber, or the optical

The fiber coupler method constitutes a resonant cavity. It has the advantages of adjustment-free, maintenance-free and high stability, which is unmatched by traditional lasers;

● Good compatibility;

● Capable of any harsh working environment, ie high tolerance to dust, vibration, shock, humidity and temperature.

Detailed Components

SUPER LASER WELDING HEAD

1--Smaller size, lighter weight,flexible operation,easy to use.Drawer type protection mirror and focus mirror,easy to change.

2--Through the connection with the laser, through the completely sealed optical channel in the cavity, an energy spot is formed

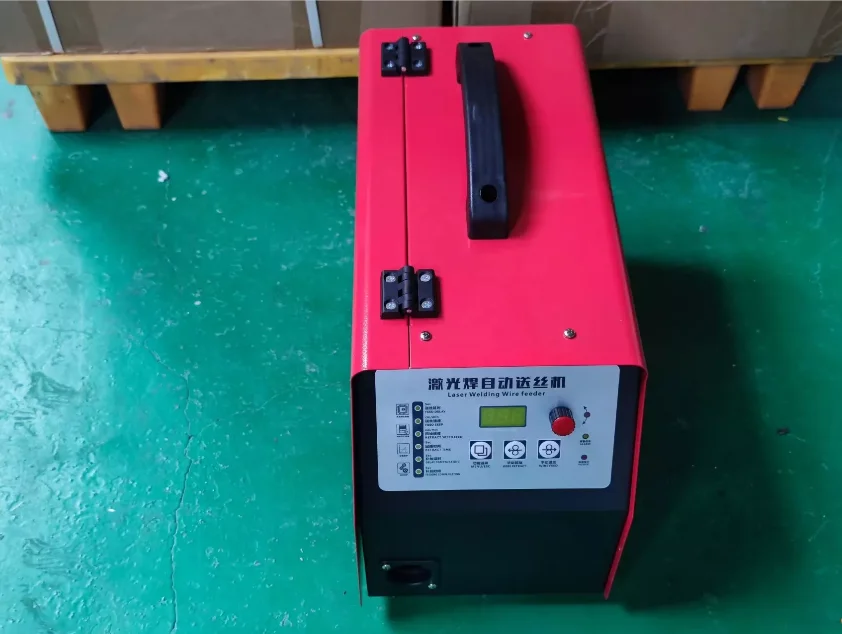

AUTO FEEDER SYSTEM

1--Industric design

2--Digital panel,easy to use and operate

3--Powerful and compact

4--Auto feeding,high efficiency

TOUCH CONTROL SYSTEM

1--Contains a variety of languages, easy to adjust,a variety of light spot control.

2--Now the software supports languages including: Simplified Chinese, Traditional Chinese, English, Korean, Russian, Spanish.

WATER COOLING SYSTEM

1--Adopt advance imported temperature control system, independent water tank switch.

2--High cooling rate, which can weld fine weld structure and good joint performance.

Welding Nozzle

1--When using different specifications of welding wire, the copper nozzle, copper guide wire nozzle and wire feed roller on the wire feeder all need corresponding

2--We will send 10 pieces for free.

LASER SOURCE

1--Raycus Brand Laser Source which can be customized according to customers

2--We have different laser generator brand and different laser power can be chosen(RECI/RAYCUS/MAX/IPG/JPT )

Samples

Application Industry & Materials

1--Fiber Laser welding machine is suitable for welding gold, silver, titanium, nickel, tin, copper, aluminum and other metals and their alloy materials. It can achieve the same precision welding between metals and dissimilar metals. It has been widely used in aerospace, shipbuilding, and instrumentation. , Mechanical and electrical products, automobiles and other industries.

2--Laser welding Machine is widely used in cabinets, kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel homes and other industries with complex and irregular welding processes; perfect replacement for traditional argon arc welding, welding on thin stainless steel plates, Welding.

Packing&Shipping

Delivery

Within 7 working days for production, we will arrange delivery after received the total payment.

Packing

Firstly, Packed the machine with plastic sheet for clearing and damp proofing.

Secondly, Then put the machine in the plywood case for safety and clashing.

Thirdly, Transport the plywood case into the container.

Patent Certificate

Our Services & Strength

1) 24 Hours online service.

2) 2 years warranty for the whole machine except for wearing parts.

3) Engineers available to service machinery overseas and also remote assistance.

4) Inquiry and consulting support.

5) View our Factory.

6) Engineers available to service machinery overseas.

7) Training how to instal the machine, training how to use the machine in our factory. We provide food and accommodation.

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion