YN999SHOP

HQD ATC Spindle 5.5KW Automatic Tool Change Spindle Motor Water-Cooled BT30 GDL120-30-18Z/5.5 CNC Milling Machine Engraving

HQD ATC Spindle 5.5KW Automatic Tool Change Spindle Motor Water-Cooled BT30 GDL120-30-18Z/5.5 CNC Milling Machine Engraving

Couldn't load pickup availability

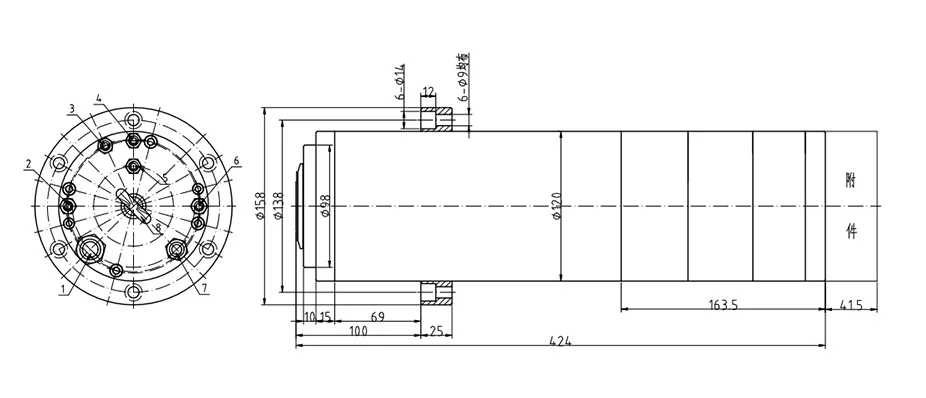

Detailed parameter introduction | |||

model |

GDL110-30-18Z/5.5 |

frequency |

600Hz |

material |

Stainless steel jacket, copper coil |

shaft end connection |

BT30 handle |

power |

5.5Kw |

Rotating speed |

18000 rpm |

diameter |

120mm |

Cone run out |

2μm |

Voltage |

380V |

cooling method |

water cooling |

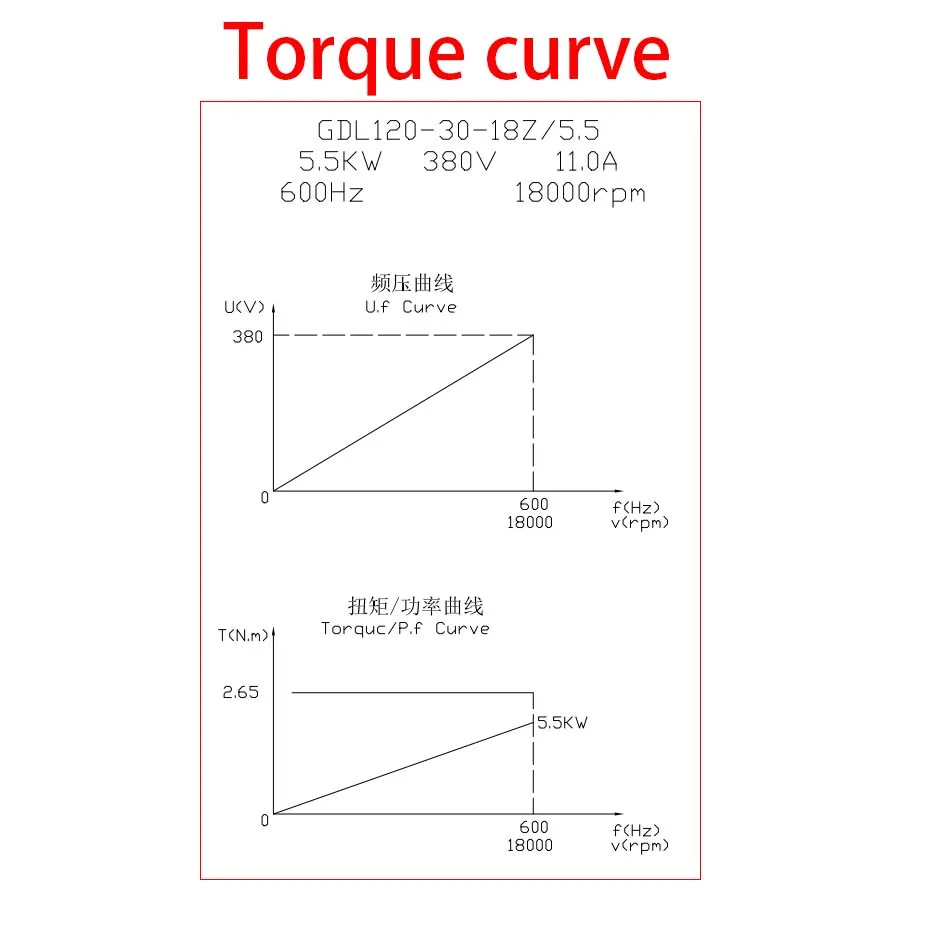

Detailed parameter introduction | |||

model |

GDL120-30-24Z/5.5 |

frequency |

800Hz |

material |

Stainless steel jacket, copper coil |

shaft end connection |

BT30 handle |

power |

5.5Kw |

Rotating speed |

24000 rpm |

diameter |

120mm |

Cone run out |

2μm |

Voltage |

220V and 380V |

cooling method |

water cooling |

Phase number |

3 |

electric current |

19A/11A |

Torque |

2.19N·m |

pole number |

4P |

1. Power cord: Three-color wire connects to U, V, W phase/yellow-green wire to ground

1. Power cord: Three-color wire connects to U, V, W phase/yellow-green wire to ground

Temperature control line: 110℃ thermistor two-phase connected to temperature control protector

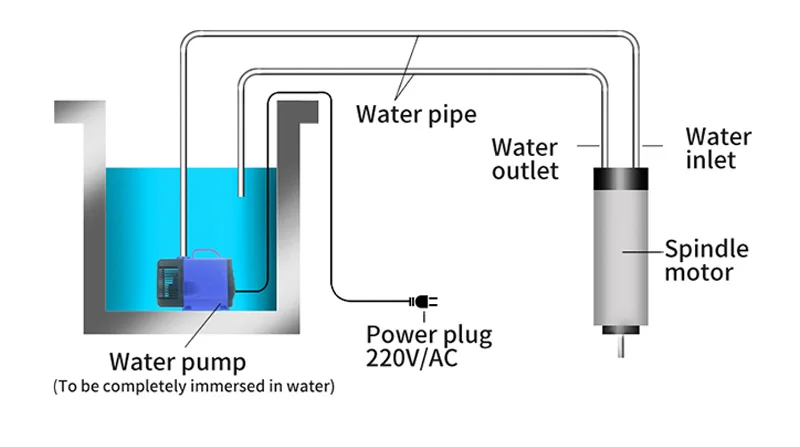

2. Cooling water outlet :(end 2 and 6 connect 8/6 hose)

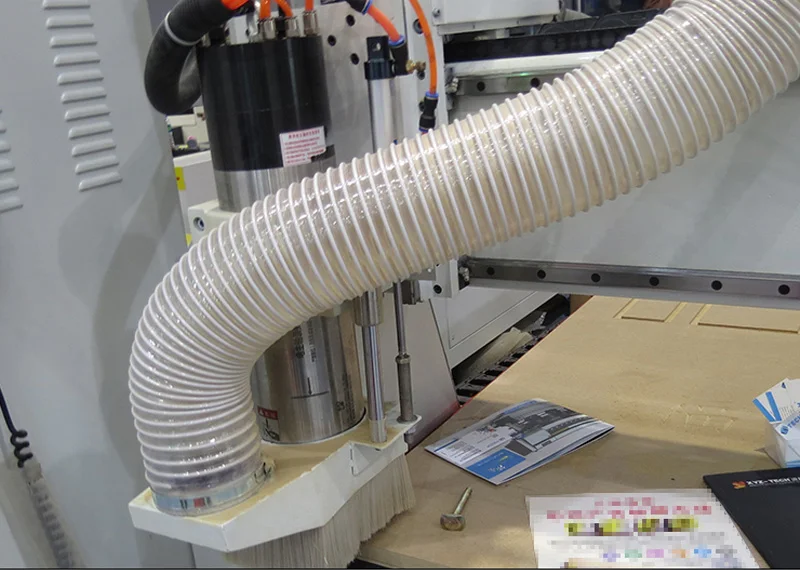

3. Knife change and dust removal pressure: 0.2-0.3MPa (6/4 hose)

4. Air seal pressure: 0.1-0.2MPa (6/4 hose)

5,Unloader inlet pressure: 0.70MPa (6/4 hose)

6. Cooling water inlet: pump head 12m (do not connect wrong!)

7. number of proximity switch: hanging knife and unloading knife two NPN(normally open) N.O

Proximity switch connection: brown wire connection +24VDC blue wire connection 0VDC

Signal load is connected to +24VDC at one end/black wire at the other end

8. Ring handle: installation and use

Special warning:

1. The electric main shaft shall be installed at the clamped position;otherwise the bearing will be easily damaged!

2. The main shaft shall entirely stop before the tool changing. Themanual tool changing button shall not act during the rotation of the shaft.otherwise it will easily result in the seizure of the shaft!

3. The compressed air shall be clean and dry, and the filter accuracyshall be 0.1micron! Air seal is normally open. It is recommended to usethe two-level filter, and the filter accuracy is 0.5 micron/ 0.1 micronrespectively. The air filter is installed with the self-discharge device.

4. lt is required to set the frequency converter strictly according to thefrequency-voltage curve of the electric shaft.

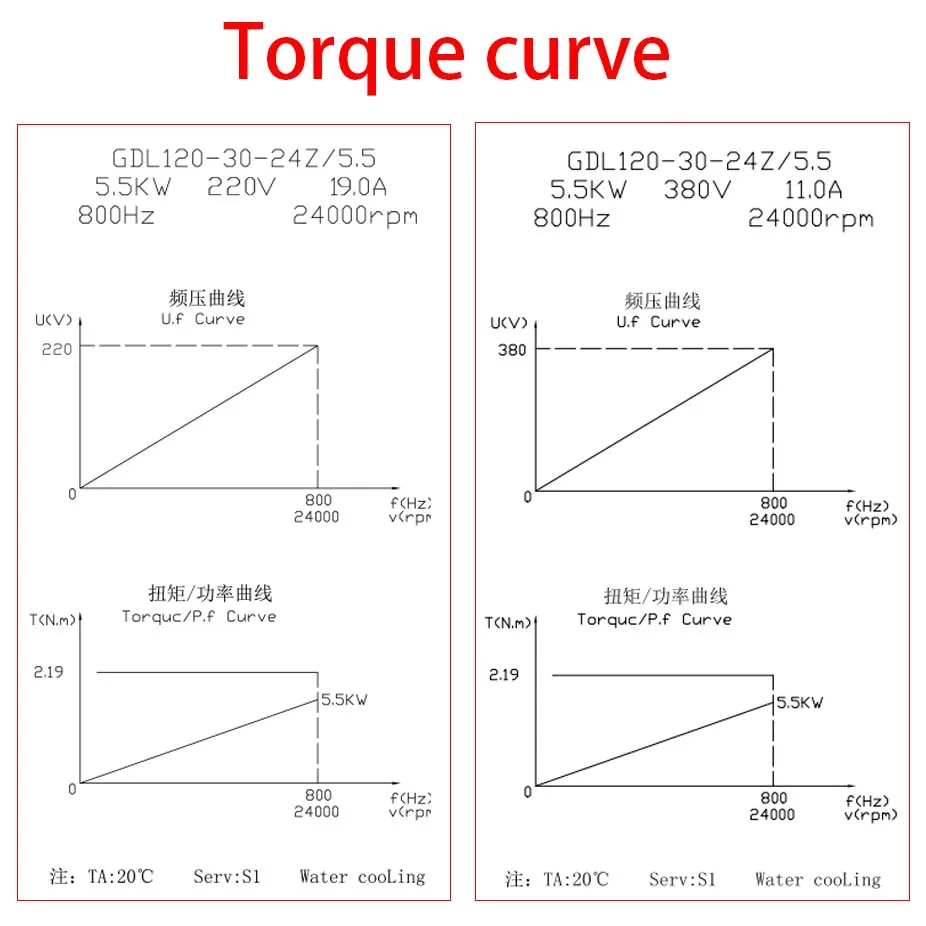

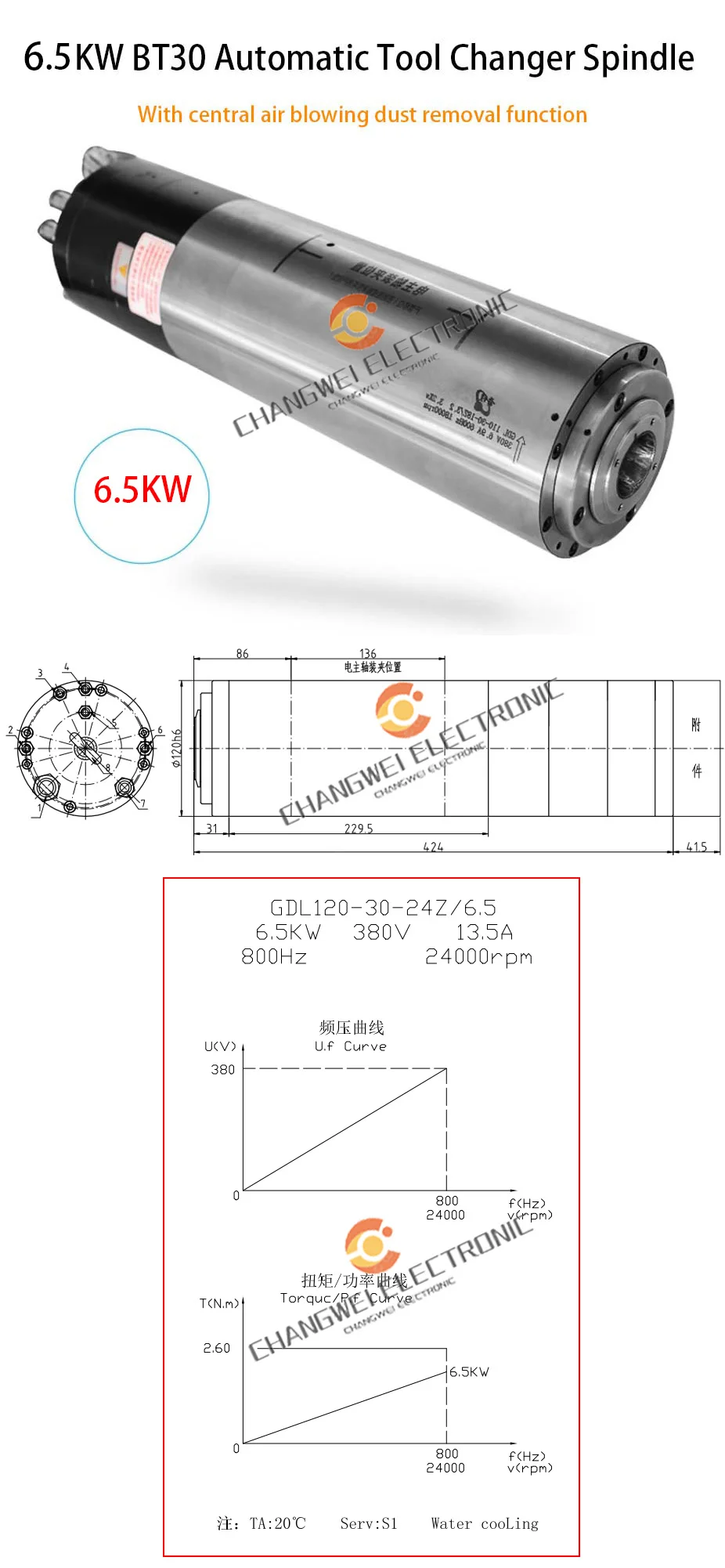

Detailed parameter introduction | |||

model |

GDL120-30-24Z/6.5 |

frequency |

800Hz |

material |

Stainless steel jacket, copper coil |

shaft end connection |

BT30 handle |

power |

6.5Kw |

Rotating speed |

24000 rpm |

diameter |

120mm |

Cone run out |

2μm |

Voltage |

380V |

cooling method |

water cooling |

Phase number |

3 |

electric current |

13.5A |

Torque |

2.6N·m |

pole number |

4P |

The working environment temperature of the spindle is usually -10~40.

The working environment temperature of the spindle is usually -10~40.

Before installing the first electric spindle to rotate the spindle head by hand, you should feel flexibility and no blockage.

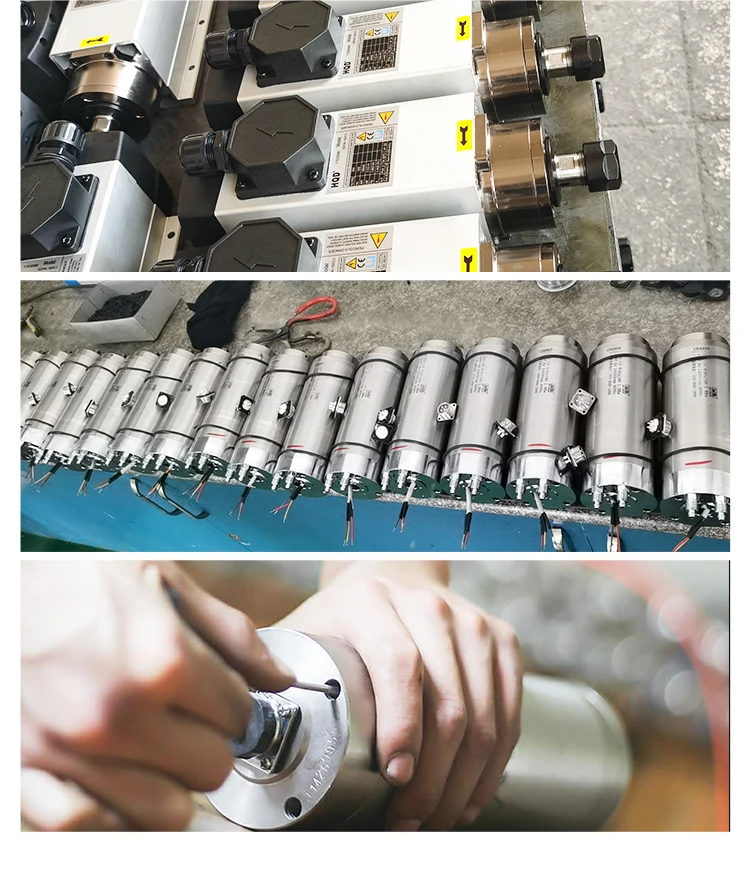

P4 fully sealed angular joint bearings can extend the life of the spindle.

P4 fully sealed angular joint bearings can extend the life of the spindle.

The longer the length, the greater the torque and the greater the power.

Careful assembly makes the spindle more precise.

The accuracy is 0.01mm, and the coaxial cable is less than 0.0025mm

1. Our main shaft uses 4 bearings.

2. Bearings are resistant to high temperature and low heat

3. The ball bearing has low friction, low noise and long service life. The water-cooled spindle must be used together with the water pump. Otherwise, the spindle will quickly break.

The water-cooled spindle must be used together with the water pump. Otherwise, the spindle will quickly break.

The AC spindle motor must be used together with the inverter. The power of the inverter needs to be equal to or greater than the power of the spindle. Before use, please set the inverter parameters suitable for the spindle. Otherwise, the spindle and inverter will break immediately.

When using the spindle, the noise is different from before, so please stop the spindle immediately. You need to replace the spindle bearing.

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion