MMOOKA

Industrial robot intelligent arc welding robot arm automatic welding equipment assembly handling automatic welding robot

Industrial robot intelligent arc welding robot arm automatic welding equipment assembly handling automatic welding robot

Couldn't load pickup availability

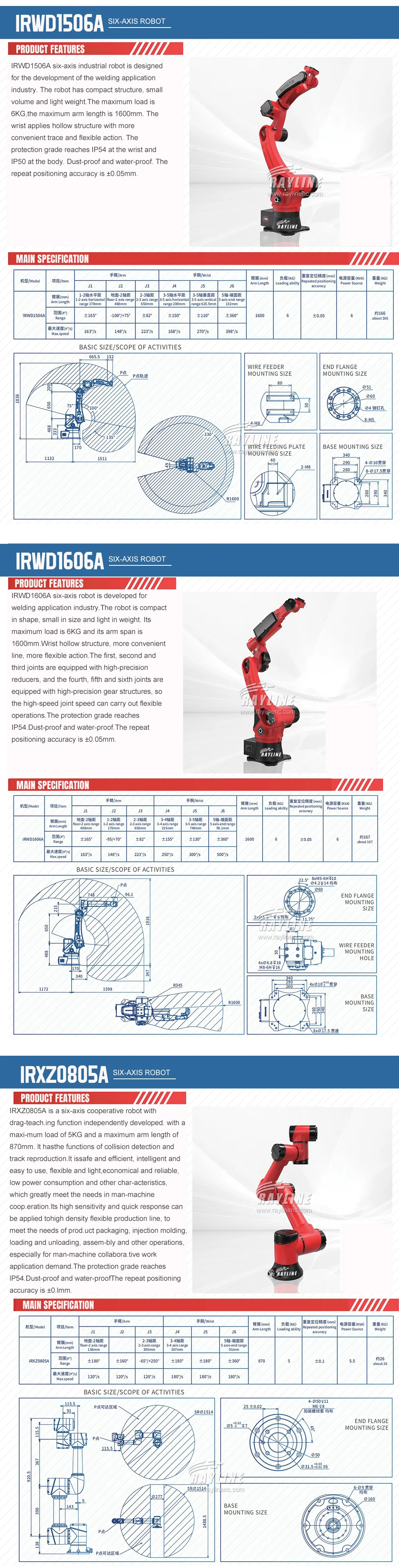

Six Axis Automatic Industry Laser Welding Robot With Two Years Warranty CNC Machine Robotic Arm for Handling Welding and Cutting

Industrial machinery Six-axis Robot Arm is a kind of automatic mechanical equipment widely used in various industrial fields. Its main functions include but are not limited. The Industrial machinery Six-axis Robot Arm is ideal for handling, welding and processing, packaging, sorting, testing, medical surgery, scientific research, etc

Machine Name |

Six-axis Robot |

Place of Origin |

China |

Warranty |

2 Years |

Applicable Industries |

Handling, welding, cutting, packaging, sorting, testing, medical surgery, scientific research, etc |

Machinery Test Report |

Yes |

Video outgoing-inspection |

Yes |

Laser wavelength |

1064nm |

Cooling System |

Waterand airCooled |

After Warranty Service |

Video Online Supportor local support |

Fiber length |

5m-10m |

Welding depth |

0.1 - 8mm |

Operating mode |

LCD Touch Screen |

Key Selling Points |

High efficiency, light and flexible |

1. Welding and machining: It can perform automated welding, cutting, milling and other processing tasks to ensure consistent product quality and high precision.

1. Welding and machining: It can perform automated welding, cutting, milling and other processing tasks to ensure consistent product quality and high precision.

2. Packaging and sorting: In the logistics and warehousing industry, robotic arms are responsible for packaging products and sorting goods, improving logistics efficiency and reducing labor costs.

3. Inspection and testing: Quality inspection and non-destructive testing of products using robotic arms, such as X-ray or ultrasonic testing, to quickly and accurately detect defects or anomalies.

4. Medical surgery: In the medical field, robotic arms are used to perform high-precision surgical procedures, helping doctors perform minimally invasive procedures, reduce risks and improve surgical success.

5. Work in dangerous environments: in extreme environments, such as nuclear power plants, deep-sea exploration, fire rescue, etc., robotic arms can replace manual work to ensure personnel safety.

6. Scientific research: In scientific laboratories, robotic arms are used to manipulate and handle experimental samples, perform precision measurements, and operate scientific equipment.

7. Handling and assembly: The robotic arm is capable of grasping, handling and placing parts to complete the assembly process of the product.

In addition, the industrial robot arm can also move objects or tools according to the requirements of spatial posture, perform various industrial operations, such as clamping welding pliers or welding guns, handling die-cast or stamping parts, laser cutting, spraying, assembling mechanical parts, etc.

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion