MMOOKA

Laser Welder Equipment 1000W Hand Held Metal Portable Fiber Laser Welding Machine 2000W 3000W with 3 in 1 Cutting Cleaning

Laser Welder Equipment 1000W Hand Held Metal Portable Fiber Laser Welding Machine 2000W 3000W with 3 in 1 Cutting Cleaning

Couldn't load pickup availability

Contact Info

Mob&Whatsapp&Wechat: +86 19306349570

Email: sales05@maxcoolcnc.com

Maxcool CNC Machinery

Laser Welder Equipment 1000W Hand Held Metal Portable Fiber Laser Welding Machine 2000W 3000W with 3 in 1 Cutting Cleaning

1/ No requirement for construction environment, high cleaning efficiency.

2/ Simple operation, low labor intensity of personnel.

3/ No noise, high degree of cleanliness, washing old as new.

4/ No pollution, synchronous cleaning and synchronous treatment, to achieve zero emissions in the cleaning process.

5/ No consumables, energy saving, green and environmental protection.

6/ No open flame, high degree of safety.

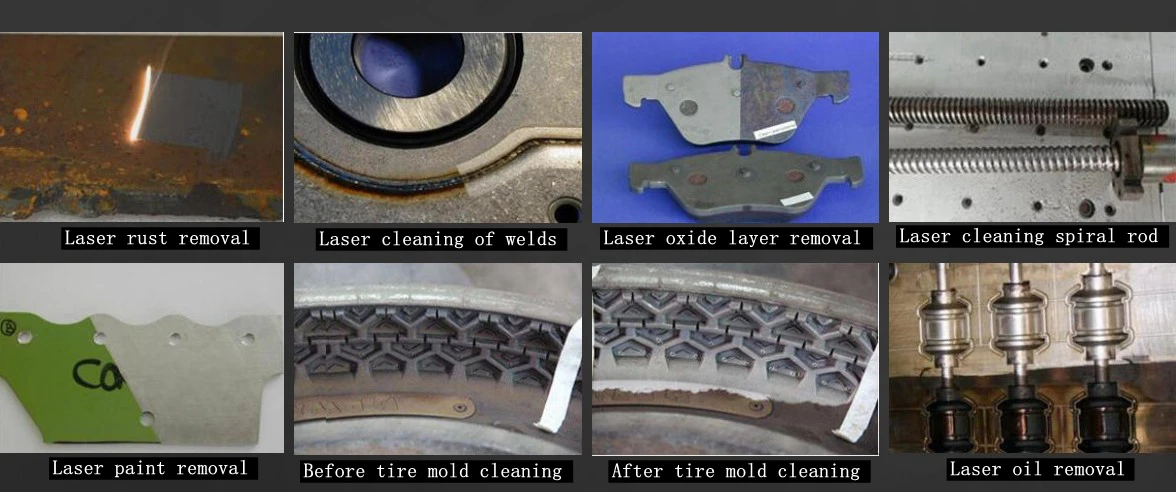

Instrument surface delamination paint removal

For high speed rail, wheel-to-shaft, enameled wire and other metal or non-metal equipment

surface implementation of micron-level precision paint removal treatment, whether carbon steel,

aluminum alloy or high-tech materials, some facilities and equipment due to process needs in the

surface of the multi-layer process.

Compared with traditional industrial cleaning methods that can only remove all layers of paint at

once, laser paint removal can remove the specified paint surface in layers without damaging the

next layer of paint, saving a lot of cost and time for repeated process painting.

Cleaning of coating plating

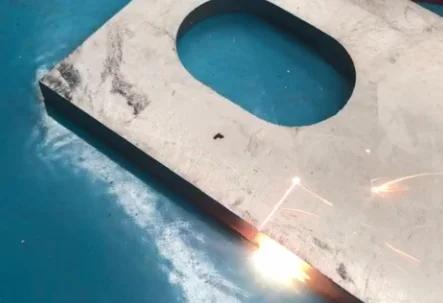

Using high-frequency high-energy laser pulses to irradiate the surface of the workpiece, the

coating layer can instantly absorb the focused laser energy, so that the surface oil, rust spots or

coatings occur instantaneous evaporation or peeling, high-speed effective cleaning method to

remove surface adhesion or surface coatings.

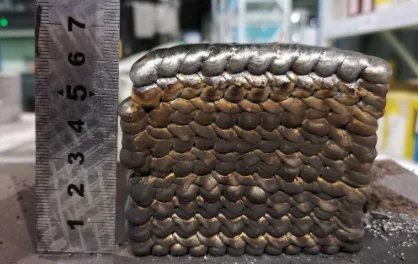

High standard metal descaling

Laser descaling is suitable for small area descaling, most cleaning high value-added products,

such as: precision parts cleaning, aerospace components, military industry, nuclear power industry,

parts microprocessing, high fine cleaning, environmental cleaning methods, high precision

industry cleaning, slide cleaning, shipyard parts cleaning, semiconductor processing, rollers,

precision parts, welding welds. Laser descaling can replace pickling phosphating cleaning

equipment, and can be used for stainless steel weld channel welding spot cleaning, titanium alloy

cleaning, welding parts cleaning.

Combustion chamber carbon removal

Dry ice cleaning has a very wide range of applications in our industrial manufacturing. Commonly

used in mold printing, automotive electronics, petrochemical and other industrial devices oil paint,

carbon adhesives cleaning, in rust and paint removal also has outstanding applications. Is an

important part of our industrial cleaning composition.

Laser cleaning is only 17 years to develop the most cutting-edge new industrial cleaning methods.

In the last two years, it has been rapidly applied to the cleaning of paint and rust removal and oil

and carbon deposits in industries such as mold and automobile.

Surface cleaning such as oil stains

Most new metal will have a thin layer of oil on it, after the metal is produced, it will be coated

with a layer of oil, the purpose of oiling is to enable the metal to reduce contact with water or

oxygen, thus slowing down the rate of rusting.

1. 3-year warranty for the whole machine, non-human damage, excluding consumables;

2-year for the generator, one year for the spindle and inverter.

2. During the warranty period, free replacement or maintenance; outside the warranty period, free technical advice and services are provided. Lifetime free software upgrades.

3. The English version of the manual or video will be sent with the machine.

4. After-sales personnel can support 24-hour after-sales service, whatsapp, email, wechat or remote control.

5. Engineers or third-party cooperative service providers can repair machinery overseas

6. CNC machines sold through dealers must be registered with MAXCOOL within 30 days of purchase in order to enjoy this warranty service

1. Whole film packaing machine.

2. Anti-collision packaging edge.

3. Fumigation-free plywood wooden box with an iron-binding belt.

4. According to the customer's requirements for loading the whole container or LCL at Qingdao Port.

5. Air transportation, rail transportation, and car transportation are all options.

Thanks for your !

Please contact me for more info ;)

Aiden 丨 Sales Manager

Phone/WhatsApp/WeChat: +86 19306349570

Email: sales05@maxcoolcnc.com

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion