MMOOKA

Metal Surface Coating Rust Laser Cleaner 3 in 1 Welding/Cleaning/Cutting Equipment

Metal Surface Coating Rust Laser Cleaner 3 in 1 Welding/Cleaning/Cutting Equipment

Couldn't load pickup availability

Contact us:

Name: Suri

Mob&Whatsapp: +86-13365319982

Wechat: 13365319982

E-mail:sales21@maxcoolcnc.com

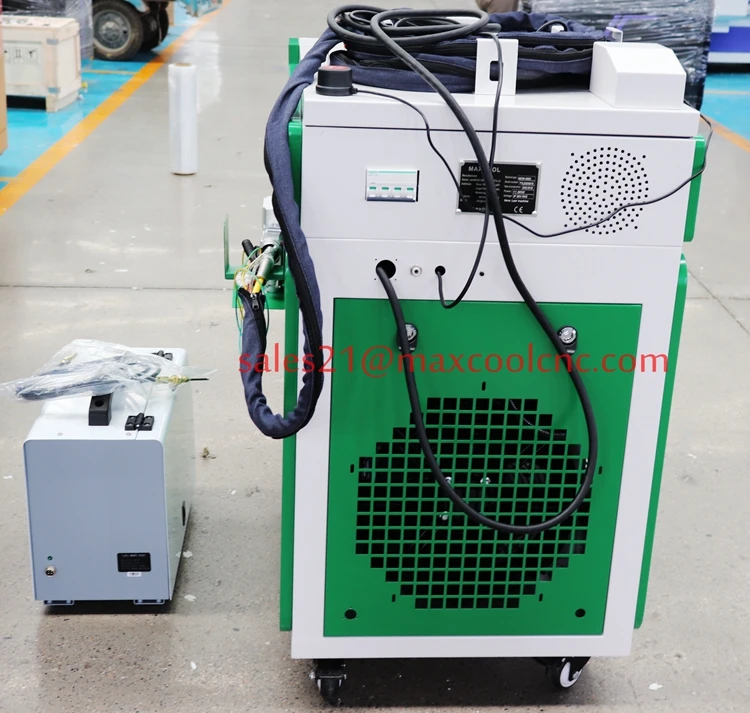

3 In 1 Welder laser cleaning machine

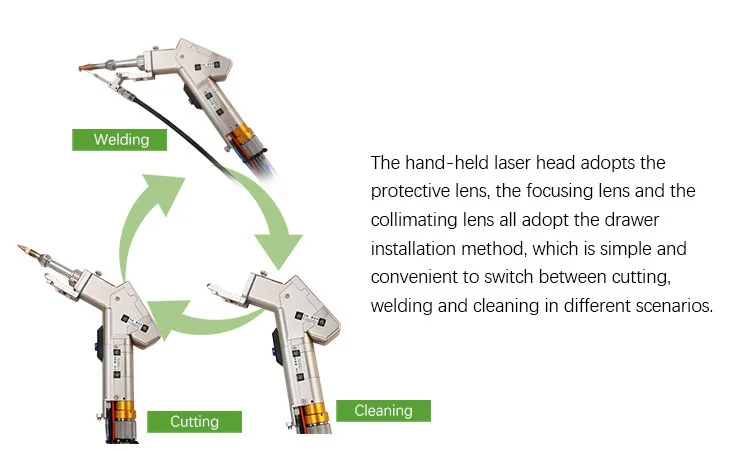

1. Multi-functions

3 working modes, welding + cutting + cleaning. Simple switching, only need to replace the copper nozzle,

switch the system

Standard length is 10m, if you have other needs, we support shortening or lengthening.

If the welding surface effect is required to be white and bright, nitrogen or argon is required

If there is no requirement for the welding surface, add compressed air freeze Dryer, air is OK.

It's the machine standard configuration, we will send to you together with the whole machine.

5. Machine warranty:

3 years for whole machine, 2 years for laser generator.

Machine features of MAXCOOL 3-in-1 Fiber Laser Machine

* Multifunctional! With welding&cleaning&cutting functions in one machine, with high effeciency for processing the metals

* Cost-Saving! With three functions in one machine, which is cheaper than get two machines!

* Easy Operate! With users manual, and operation video which is easy to learn and use!

* High performance! Works well on cleaning and welding the material. Good at Metal Processing!

Control system:

Au3tech controller. Which has Strong compatibility, Multiple light emission modes.

It is Maintenance-free, and has a long service life.

Au3tech 3-in-1 machine can support 17 languages now, most customers' demand can be satisfied

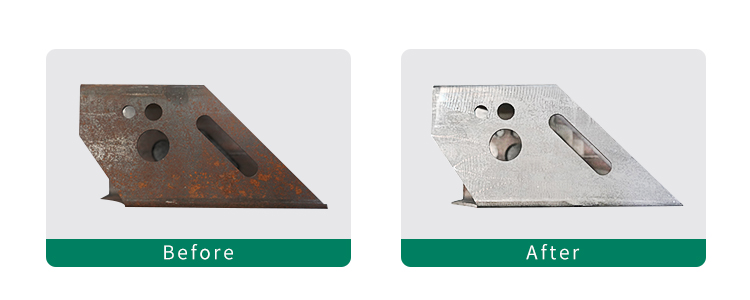

Laser cleaning function:

1) Laser Rust Removal: Laser light can easily remove rust, after removal, the surface is restored to a bright metallic color or restoration of the original base color.

2) Laser Oil Removal: Metal surface oil cleaning (can remove oxide film at the same time)

3) Laser Paint Removal: removes various paints including auto Duco on various substrates and automobiles

4) Stripping coating (galvanized layer, aluminized layer, protective coating, etc.)

5) Removal of aluminum alloy, titanium alloy, copper alloy oxide film

6) Pre-Weld Pretreatments: After laser cleaning pretreats the aluminum alloy, the welding porosity defects are effectively suppressed

7) Cleaning after welding: Non-Contact NDT removal of post-weld oxide film and slag residue

8) Aluminium alloy pulsed lasers remove dirt and oxide film before welding

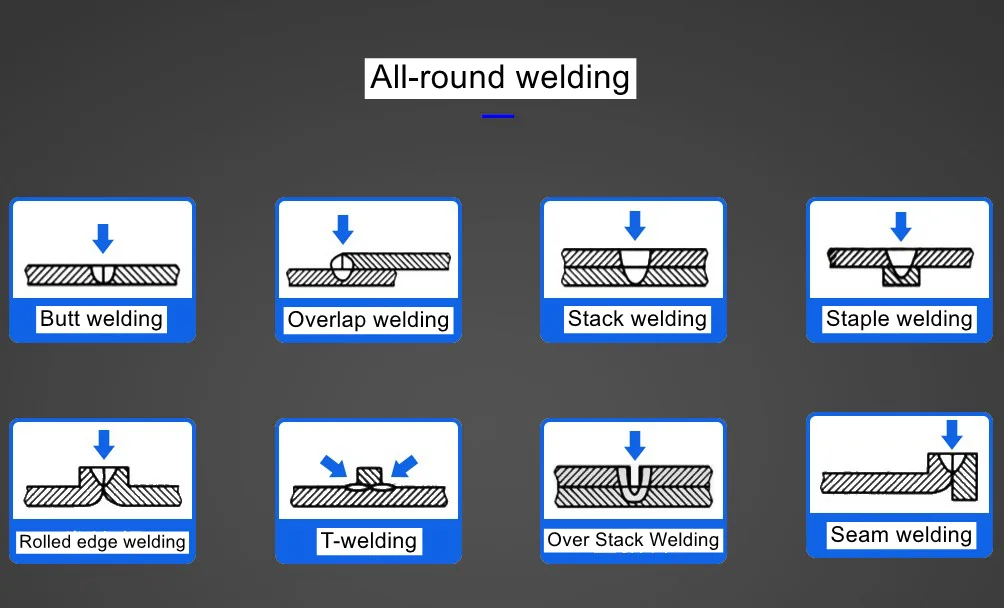

Laser welding function:

Laser welding can be used in welding stainless steel, aluminum, copper, gold, silver, chromium, titanium and other metals or alloys, can also be used for a variety of welding between different materials.

Wildly used in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window

guardrail, distribution box, stainless steel home.

!

!

Application industry

Contact us:

Contact us:Name: Suri

Mob&Whatsapp: +86-13365319982

Wechat: 13365319982

E-mail:sales21@maxcoolcnc.com

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion