MMOOKA

Stainless Steel aluminum alloy 1500W handheld laser welding equipment for metal fittings/cabinets

Stainless Steel aluminum alloy 1500W handheld laser welding equipment for metal fittings/cabinets

Couldn't load pickup availability

Feature of Machine

The fiber continuous welding machine is a high-end, new type of welding method.

It is generally composed of a "welding mainframe" and a "welding workbench".

The laser beam is coupled to the optical fiber, and after being transmitted over a long distance,

it is processed into parallel light. Focusing on the workpiece to perform continuous welding,

the welding effect is stronger due to the continuity of the light output, and the weld seam is

more fine and beautiful. According to the different needs of different industries, the equipment

can meet the needs of users in different industries according to the matching shape and workbench

on the production site and the automation work.

Product Introduction

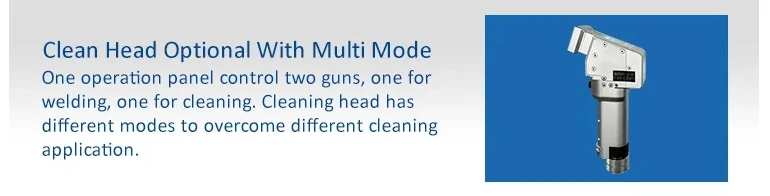

Laser Welding Head

Specification

1.Hand held Fiber Laser welding Machine

2.Power:1000W 1500W 2000W

3.Laser wavelength:1070NM

4.Fiber length:Standard 10M. Max: 15M

5.Chiller:Industrial constant temperature water tank

6.Temperature range of working environment:15-35 ℃

7.Humidity range of working environment:< 70% No condensation

8.Welding gap requirements:≤0.5mm

9.Voltage:220V

Applicable Industries

The laser cleaning machine can efficiently remove resin, oil stains, stains, dirt, rust, coating, plating, and paint on the surface of the workpiece, meeting the cleaning requirements of complex shapes and fine positioning in the industrial processing field, achieving a cleaner cleaning effect with higher cleanliness, and a higher overall cost.

Advantages

1. It can weld some other components that are easy to be damaged or cracked during welding without contact and will not cause mechanical stress to the welding object

Package

1.Outside package: Strong wooden case.

2.Inner package: Water-proof plastic film package with foam protection in each corner Solid Seaworthy Wood Box Package.

Fumigation-free packaging size:103*65*126cm (could ship via air)

Total weight:175KG

FAQ

1. What's material can fiber laser weld?

All kinds of metal, such as Stainless Steel,Carbon Steel, Mild Steel, Galvanized Steel, Aluminum, copper, etc.

2.Which fiber source does we applied

Raycus- Made in China;

RECI - Made in China;

3.What's the thickness of a laser Welding Machine could weld?

1000W could weld Stainless Steel and Carbon Steel Up to 3mm, Aluminum and Brass to 1.5mm.

1500W could weld Stainless Steel and Carbon Steel Up to 5mm, Aluminum and Brass to 2mm.

2000W could weld Stainless Steel and Carbon Steel Up to 7mm, Aluminum and Brass to 4mm.

How to place a order:

contact me for more details thanks.

Share

Collections

-

Coffee Machine

Coffee Machine Italian Full & Semi Automatic Household Cafetière Small Foam Grinding...

-

Drill brush

Drill brush

-

Heavyweight silk

Heavyweight silk , French silk cotton lace bed set with four pieces

-

Massage chair

Luxury Smart Full-Body Zero-Gravity Shiatsu Massage Chair Airbag Surround Bluetooth Music Massage...

-

Wedding Dress

Women Luxury Beaded Bridal Mermaid Wedding Dress Floral Ruffles Sparkly Illusion